For individuals who require oxygen therapy, the ability to travel comfortably and safely is essential. A portable oxygen concentrator for travel offers a game-changing solution, enabling freedom and mobility without sacrificing health needs.

How clever engineering and materials science, aided by electronics, can overcome physical filtering dilemmas…

Analog system designers typically choose and use a variety of low-pass, high-pass, notch, and band-pass filters, as well as filters that use mathematical principles such as Butterworth, Kaul, or Chebyshev. Regardless of the filter type, in most cases they do not have to worry about “dealing with” the signal that the filter removes. In fact, I suspect that if you ask engineers, most of them probably never think about or even know what happens to the signal that is filtered out; it just disappears “somewhere.”.

Of course, this is not the case, and the answer is actually very simple: the energy of the filtered signal becomes heat. In most cases, the heat is so negligible that it can be ignored, but this is not always the case. If you want to filter out 10% of the energy in a 100W transmitter signal, you need the filter components to be able to handle the 10W dissipation and the system design to be able to accept the additional heat load. This challenge can surprise novice engineers, who will think, “No big deal, we just filter the signal” without considering the possible thermal impact.

Engineers who filter gaseous or liquid fluids do not necessarily face thermal dilemmas, but they may face more challenging ones. In the course of their work, filters may fill or become clogged and need to be replaced or cleaned. Lint filters in dishwashers, vacuum cleaners, or washing machines are common consumer examples. A sensor may even be needed to alert the user that the filter is no longer working.

I recently saw another example of how electronic circuit designers have it easy compared to mechanical and fluid engineers and how clever engineering and materials science knowledge, aided by electronics, can overcome physical filtration dilemmas.

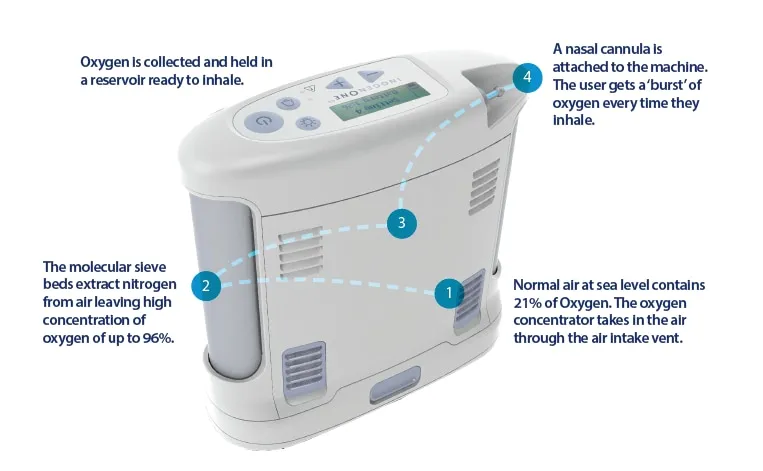

A friend with lung and breathing problems switched from using separate pressurized oxygen tanks to using the Inogen One G4 Portable Oxygen Concentrator (Figure 1). He gained a great sense of personal freedom by giving up the heavy oxygen tanks (which also needed to be replaced every few days) for a small, fully portable device weighing 3.3 pounds (1.5 kg).

How does this device work? What filtration problems does it have to solve? The secret to its successful design is not just one, but a combination of factors. It is important to keep in mind the design goals and constraints. The device needs to “purify” the ambient air and provide the user with nearly 100% oxygen. The device must be small, quiet, lightweight, and have a battery that can run continuously for at least several hours.

In addition, as a medical device, it must also meet safety and regulatory requirements such as fail-safe operation and self-tests and must be easy to use and maintain. Of course, simple is a relative word, and here it means that no maintenance, air filter replacement, or adjustments of any kind are required.

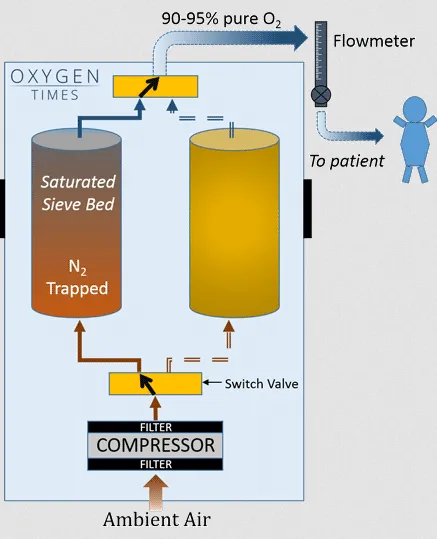

The design of the oxygen concentrator starts with the fact that ambient air as a raw material can be “filtered” for use because it contains 78% nitrogen, 21% oxygen, and 1% other gases (carbon dioxide, argon, etc.). If the nitrogen can be filtered out, the main gas left is oxygen with a purity of about 90-95%, which is good enough.

So, how to remove the nitrogen? The initial thought was that it would require some kind of complex chemical reaction, with the need to empty the consumed materials, replace the reagents, and other related hassles. This would have been extremely complex and unacceptable from a simplicity and reliability standpoint.

That’s when mineral and materials experts offered a relatively simple solution: a “sieve bed” of zeolites (microporous aluminosilicates) that can capture nitrogen. In this case, the capture is done not by absorption or forming new compounds but by adsorption. That means the nitrogen clings to the surface of the zeolite (similar to magnets and iron) but doesn’t form any new molecular combinations with it.

Not familiar with zeolites? Check out the NIH/National Library of Medicine article “Zeolite Clinoptilolite: Therapeutic Virtues of an Ancient Mineral” for a brief introduction.

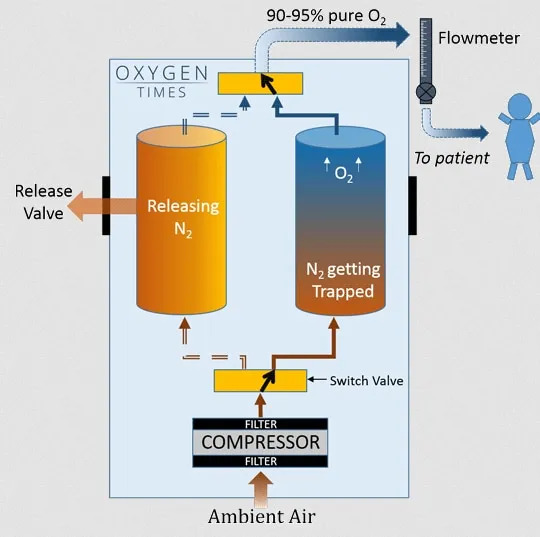

To solve the problem of filter clogging and replacement, the designers used a technique that has been employed in other systems, but here it’s used on a smaller scale. They used two identical sieve beds, one for adsorption and the other for flushing.

The unit’s compressor pumps air into the first molecular sieve bed until it fills with unneeded nitrogen. When this happens, an electronically controlled on-off valve (the fluid equivalent of a single-pole/double-throw switch) flips and sends unfiltered air to the second sieve bed. The second sieve bed is not there for redundancy (as I initially thought it was), but is required for basic operation while another on-off valve outputs the second sieve bed’s product to the user.

That’s not the end of the sieve bed filtration cycle. As the second sieve bed is activated, the trapped nitrogen in the first sieve bed is also purged. This allows the first sieve bed to take over from the second sieve bed as it fills. Because the sieve beds are cycled and purged, there is always a clean filter ready to take over from the nitrogen-filled sieve bed without the user having to change filters.

To achieve this, it takes more than a dual sieve solution. In addition to the on-off valves, there are many sensors for pressure, airflow, power system monitoring and management, and other key points for operational and safety needs. The smooth integration of electronic components with common specialty materials, fluid management, and filtration results in a product that is complex on the inside but extremely simple to use and maintain.

In conclusion, a portable oxygen concentrator for travel is more than just a medical device—it’s a gateway to freedom and independence for those requiring oxygen therapy. By combining advanced technology with user-friendly features, these devices ensure that health needs are met without limiting mobility. Whether you’re planning an international trip or simply enjoying local outings, a portable oxygen concentrator empowers you to embrace life fully and confidently. With the right model and proper preparation, travel becomes not only possible but enjoyable.